Concrete End Hose Pipe

Concrete End Hose Pipe – An essential component in construction, a concrete end hose pipe facilitates the precise and efficient transfer of concrete from the pump to the intended surface. Constructed with robust materials, it ensures a reliable flow of concrete while withstanding pressure and abrasion. This flexible tool is vital for reaching challenging areas and maintaining a continuous concrete placement process. Its durability and adaptability make it indispensable in various construction projects, from buildings to infrastructure. The concrete end hose pipe streamlines the concrete placement process, enhancing project efficiency and contributing to the creation of sturdy structures.

A concrete end hose pipe is a vital element within concrete pumping equipment, facilitating the secure and efficient conveyance of concrete from the pump to the desired construction site. Constructed to endure high pressure and the abrasive nature of concrete, while retaining flexibility for maneuvering, it comprises essential components:

- Inner Tube: The core part made of abrasion-resistant synthetic rubber, responsible for transporting the concrete from the pump to the delivery point.

- Reinforcement Layers: These layers, often steel wires or fabric, enhance structural integrity, enabling the hose to withstand the immense pressure exerted by the concrete.

- Outer Cover: A protective layer of synthetic rubber shielding the hose from weather, abrasion, and impact.

- End Fittings: These connectors, typically steel, securely attach the hose to the pump and delivery point, ensuring a leak-free link.

- Couplings: Quick connectors aiding setup and disassembly of the concrete pump by linking the hose to the end fittings.

- Flanges: Bolted connectors at the end fittings, creating a secure junction between the hose and other components.

- Bend Restrictors: Durable plastic/rubber parts preventing excessive bending and kinking, sustaining smooth concrete flow and extending hose life.

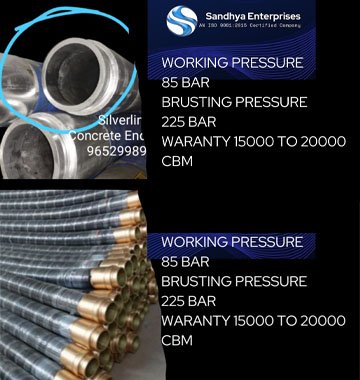

- Pressure Ratings: The hose is designed for specific pressure levels, based on equipment capabilities and project demands.

Working Principle Of A Concrete End Hose Pipe :

- Concrete end hose pipe is a vital part of concrete pumping equipment for smooth concrete transfer during construction.

- It attaches to the concrete pump’s outlet, utilizing hydraulic power and flexibility for efficient concrete delivery.

- The hose is constructed with robust materials like rubber to withstand high-pressure, abrasive concrete.

- Flexibility of the hose allows easy navigation around obstacles, ensuring precise concrete placement.

- Smooth interior surface reduces resistance during concrete transfer.

- Design balances strength and flexibility to accommodate pump movements without stressing equipment or concrete line.

- Reinforced construction enhances hose longevity, minimizing blockage risks and concrete flow disruptions.

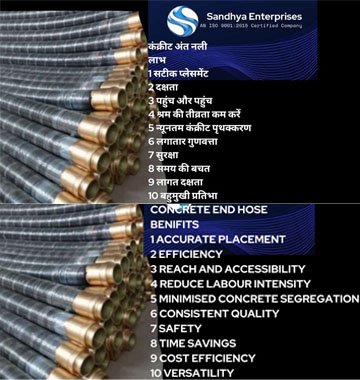

Advantages Of Using A Concrete End Hose Pipe :

- Extended Reach and Flexibility: Concrete end hose pipes extend the reach of concrete pumps, enabling precise placement in challenging areas and navigating obstacles efficiently.

- Accuracy and Consistency: These hoses ensure a uniform flow of concrete, leading to accurate placement as per plans and minimizing wastage.

- Time and Labor Efficiency: Quick and precise concrete delivery reduces project delays, minimizes manual labor, and speeds up construction.

- Enhanced Safety: Concrete end hose pipes eliminate heavy lifting and repetitive movements, promoting a safer work environment and reducing injuries.

- Cost Savings: Initial investment in pump systems and hoses pays off with reduced labor, faster work pace, and less material wastage.

- Segregation Minimization: Hose pipes maintain concrete integrity during delivery, preventing aggregates from separating and resulting in stronger structures.

- Versatility: Available in various lengths and diameters, suitable for a wide range of projects from residential to large-scale infrastructure.

- Environmental Friendly: Controlled delivery reduces spillage, conserves water and energy, and minimizes environmental impact.

Types Of Concrete End Hose Pipes :

Concrete end hose pipes play a vital role in efficient concrete pumping, transferring concrete precisely. They vary by type to suit specific needs:

- Wire-Reinforced Hoses: Strong steel-wire reinforcement handles high pressures effectively.

- Fabric-Reinforced Hoses: Nylon/polyester layers offer flexibility for tight spaces.

- Steel-Plastic Composite Hoses: Blend steel and plastic for durability and flexibility.

- Abrasion-Resistant Hoses: Shield against abrasive materials, extending lifespan.

- Reducing Hoses: Transition smoothly from large to small diameter, preventing blockages.

- High-Pressure Hoses: Withstand elevated pressures for long-distance or high-elevation pumping.

- Long-Reach Hoses: Deliver concrete over extended distances or heights while preserving quality.

- Smooth Interior Hoses: Ensure consistent concrete flow, reducing clogs.

- End Hose Extensions: Add length without compromising efficiency.

- Specialty Hoses: Tailored for unique conditions like extreme temperatures or chemicals. Selecting the right hose hinges on pressure, diameter, length, and project specifics. Maintenance and checks are vital for longevity and safety.

Maintenance And Care Of Concrete End Hose Pipe :

To ensure the longevity and optimal performance of a concrete end hose pipe, regular maintenance and care are crucial. Firstly, after each use, thoroughly clean the hose inside and out with water to prevent concrete buildup. Inspect the hose for any signs of wear, cracks, or damage, and promptly repair or replace as needed. Store the hose in a dry, shaded area, away from direct sunlight and harsh weather conditions, to prevent degradation. Avoid dragging the hose across rough surfaces to prevent abrasion.

Additionally, always handle the hose with care to prevent kinks and twists that can restrict the flow of concrete. Regularly check the connections and fittings for leaks and ensure they are properly tightened. Lubricate the fittings as recommended by the manufacturer to maintain flexibility. Adhering to these maintenance practices will prolong the life of the concrete end hose pipe and ensure its reliability during concrete placement tasks.

Safety Measures Of Concrete End Hose Pipe :

- Inspection: Regularly inspect end hose pipes for wear, damage, cracks, and leaks.

- Storage: Keep hoses in a dry, shaded area away from extreme temperatures.

- Handling: Train personnel to handle hoses carefully, avoiding impacts and drops.

- Connections: Ensure secure and tight connections, clamps, and couplings.

- Pressure Ratings: Use hoses with proper pressure ratings to prevent bursts.

- Length: Choose appropriate hose length to avoid stress and maintain efficiency.

- Abrasion Protection: Guard hoses against abrasion using sleeves or guards.

- Bending Radius: Don’t exceed recommended bending radius to prevent weakening.

- Kink Prevention: Avoid kinking that obstructs concrete flow.

- Concrete Mix: Use specified concrete mixes to prevent accelerated hose wear.

- Operator Training: Provide thorough equipment and safety training.

- Emergency Shutdown: Educate operators on swift and safe shutdown procedures.

- Emergency Response: Develop clear protocols for incidents like hose bursts.

- PPE: Enforce use of proper PPE for all personnel.

- Communication: Maintain clear communication through signals or radios.

- Avoid Overloading: Prevent overloading beyond hose capacity.

- Regular Maintenance: Follow maintenance schedule for all system components.

Proper Handling And Operation Of Concrete End Hose Pipe:

Proper handling and operation of concrete end hose pipes are crucial to ensure safe and efficient concrete placement. Firstly, inspect the hose for any damage or wear before each use. Maintain a suitable radius to prevent kinks or bends that can obstruct concrete flow. Securely attach the hose, avoiding sharp bends or abrupt angles that may restrict concrete movement. Regularly clean the hose interior to prevent blockages and buildup. During operation, avoid excessive whipping or sudden movements to prevent damage to the hose and ensure personnel safety. Adequate support and minimal dragging on rough surfaces will prolong the hose’s lifespan. After each use, flush the hose with water to prevent concrete residue from hardening. Following these practices will guarantee the longevity of the concrete end hose pipe, enhance worksite safety, and maintain the quality of concrete placement.

Common Challenges And Troubleshooting :

- Blockages: Concrete end hose pipes can experience blockages due to hardened concrete or debris, leading to reduced flow or complete clogs.

- Abrasion: The hose’s inner lining can wear down due to abrasive concrete materials, potentially causing leaks or reduced efficiency.

- Kinking: Improper handling or storage can cause the hose to kink, obstructing the concrete flow and causing pressure buildup.

- Leaks: Fittings or connections might develop leaks if not secured properly or if subjected to excessive pressure.

- Bursting: Excessive pressure or wear and tear can cause the hose to burst, potentially damaging equipment and causing safety hazards.

- Material Buildup: Concrete buildup within the hose over time can decrease its diameter, impacting the flow rate and potentially causing blockages.

- Handling Issues: Inadequate handling can lead to physical damage, weakening the hose’s structure and reducing its lifespan.

- Temperature Effects: Extreme temperatures can affect the hose’s flexibility and integrity, leading to cracks or reduced performance.

- Chemical Degradation: Concrete’s chemical components can react with the hose material, causing it to degrade and weaken over time.

- Maintenance Lapses: Inadequate maintenance and inspection can result in undetected issues that worsen over time. Regular checks and maintenance are essential.

To troubleshoot these challenges, regularly inspect the hose for signs of wear, ensure proper storage and handling, clean the hose after use, and follow manufacturer guidelines for pressure and temperature limits.

Real-Life Applications And Examples:

Concrete end hose pipes are crucial components in construction and concrete placement processes, facilitating the controlled discharge of concrete mix. These pipes are versatile and find application in various real-life scenarios:

- Concrete Pumping: The primary purpose of end hose pipes is to connect concrete pumps to the placement area, allowing for efficient and precise concrete delivery.

- High-rise Construction: In tall buildings, end hose pipes enable concrete to be pumped to elevated floors with accuracy, saving time and labor.

- Infrastructure Projects: Bridges, tunnels, and roads benefit from these hoses as they can reach and deliver concrete to remote or hard-to-access areas.

- Reduced Labor: End hose pipes minimize the need for manual transportation and pouring of concrete, reducing labor costs and fatigue.

- Enhanced Flexibility: These pipes offer flexibility to adjust the concrete placement area without relocating the entire pump setup.

- Large-scale Projects: Mega projects like dams and industrial structures rely on end hose pipes to ensure a continuous and controlled concrete flow.

- Minimized Wastage: By delivering concrete directly to the intended location, wastage is minimized compared to traditional pouring methods.

- Improved Safety: Workers are less exposed to potential hazards as they can operate the pump and guide the hose from a safer distance.

- Time Efficiency: The speed of concrete placement through end hose pipes accelerates project completion compared to manual methods.

- Consistency: Uniform concrete distribution is achieved, resulting in consistent quality throughout the structure.

In sum, concrete end hose pipes are indispensable in modern construction, enabling efficient, safe, and precise concrete placement in a wide range of applications.

Conclusion And Recap:

In conclusion, the concrete end hose pipe is a vital component in construction projects, facilitating the precise and efficient delivery of concrete to desired locations. To recap its significance and features:

- Precision: The hose pipe enables accurate concrete placement, reducing wastage and ensuring uniform distribution.

- Flexibility: Its flexible design allows maneuverability around obstacles and challenging spaces, enhancing construction adaptability.

- Time Efficiency: The hose pipe expedites the concrete pouring process, saving time and labor costs.

- Reach: With extended lengths, it reaches distant or elevated areas, minimizing the need for manual transport.

- Wear Resistance: Constructed with durable materials, it withstands the abrasion caused by high-pressure concrete flow.

- Maintenance: Regular maintenance ensures longevity and consistent performance.

- Project Versatility: From residential to large-scale projects, the hose pipe suits various construction needs.

In essence, the concrete end hose pipe is an indispensable tool that optimizes concrete placement, offering efficiency, flexibility, and durability to construction endeavors.