Dam Gate Rubber Seal

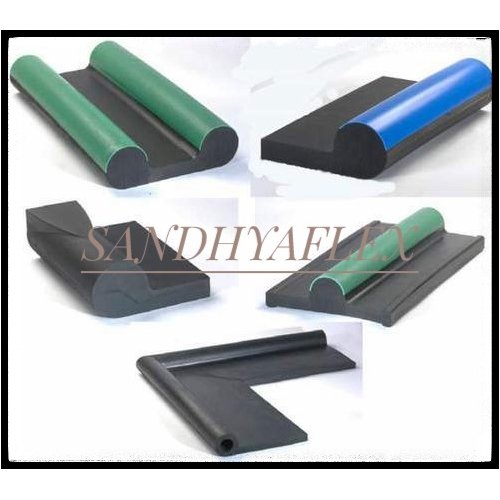

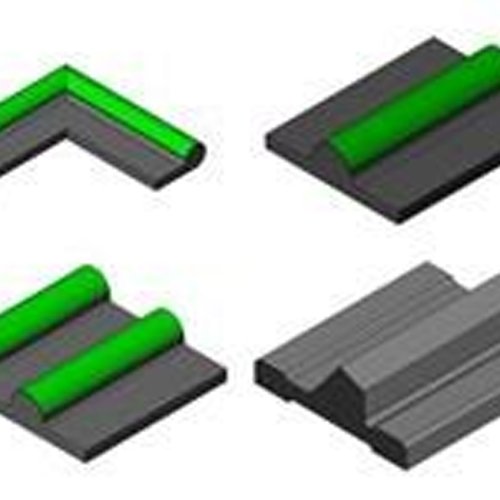

Common sizes and the arrangement of music note seal over the seal base plate. The initial interference note type seal shall vary from 2 to 5 mm depending upon the requirement and type of its installation discretion of the designer.

The music note seal is generally recommended to be used on gates operated for head up to 30 metres. hollow bulb music note seal is recommended for gates operated at low head up to 15 metre.

A solid bulb music note seal is recommended for gates operated at medium head, that is at a head

exceeding 15 m but less than 30 m

Sandhya Enterprises is renowned manufacturer and supplier of various types of Rubber Dam Gate Seals in Hyderabad Telangana, India. These rubber seals are being used in various Irrigation as well as Hydropower projects since many years. Dam gate seals are designed to either retain water, prevent water penetration, or limit contaminated run off in civil engineering a

Dam Gate Seals Application:

Quality of Rubber Concept dam gate seals are very well accepted by various Gate Designers, Fabricators as well as Contractors, and been installed by Government and Private agencies. We have supplied numerous dam gate seals for number of dams across India and abroad, for various types of Gate designs such as following and many more.

The inherent elasticity and resilience of Rubber Concept dam gate seals allow it to retain its sealing effectiveness in situations where there are fluctuating movements caused by water pressure, traffic, subsidence or seismic movement.

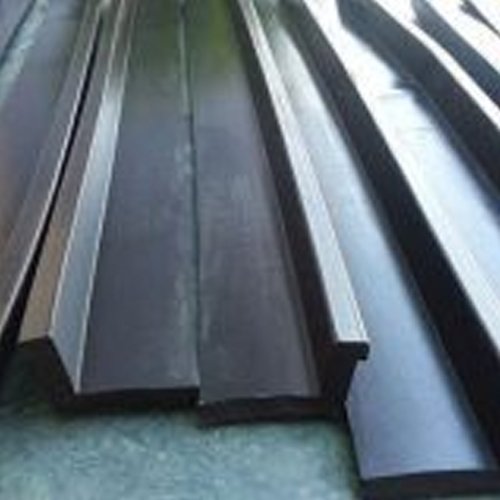

Dam Gate Seal Types:

Depending on the head pressure, gate designers design gates and based on the design of gates, seals are selected

- Musical Note seal: Also known as P-type seal or J- type or single stem seal. Generally used in low head gates, can be available with solid as well as hollow bulb. PTFE (Teflon) cladding available

- Double Stem seal: Generally used in high head gates, PTFE (Teflon) cladding available

- Z-type rubber seal: Used in Radial gates, PTFE (Teflon) cladding available

- Flat Seal: Used as bottom seal, wedge or radius options available

- Special design seal: customized rubber seals

- Dam gate seal Corners: factory moulded or fabricated options available

Dam Gate Seal Materials Used:

Compounds, based on following elastomers, are used for the manufacturing of Rubber Dam Gate Seals:Natural Rubber (As per IS: 11855 / IS: 15466)

- EPDM Rubber

- PolyChloroprene Rubber / Neoprene Rubber

Dam Gate Seal Manufacturing:

Sandhya Enterprises produces Dam gate seal by Moulding method, Quality of which is better than extruded seals. Pressurized curing during moulding ensures close dimensional control, superior physical properties, compact microstructures, thus improved durability and functionality.

Rubber Dam Gate Seals ImagesIS 15466 Certificate

We can make the parts with good quality and highly appreciated service according to your drawing with dimensions or samples. This all gates seals are manufacturing conforming to IS: 11855 -1986 or IS: 15466 – 2004 Specificaiton.

Quality:

All raw materials such as Carbon Black, Oils, Rubber Chemicals, etc. are checked in house laboratory, by a team of chemist and lab experts for ensuring the quality of incoming materials. All other row and sami finish materials are directly received from Branded Companies like Cabot India / Philips Carbon, HP Oils / IPOL, DuPont, Buyer, Lanxess, Nocil Chemicals.

DAM GATE RUBBER SEAL COMPOUNDS, BASED ON FOLLOWING ELASTOMERS, ARE USED FOR THE MANUFACTURING OF RUBBER DAM GATE SEALS :

- Natural Rubber

- EPDM Rubber

- Poly Chloroprene Rubber

- Neoprene Rubber

MIXING & COMPOUNDING

In this process we are mixing the supporting ingredient in to the raw rubber to enhance its property. We are always follows the standards in making production. Mixing and Rubber Compounding with a formula to fabricate the desired product or article.

WE FOLLOWS TWO STAGE MIXING PROCESS IN ORDER TO GET THE BEST PROPERTIES OF RUBBER.

- Stage 1 : carbon black and other non-vulcanizing additives are combined with the raw rubber The term master batch is used for this first stage mixture.

- Stage 2 : after stage 1 mixing has been completed, and time for cooling has been allowed, stage 2 mixing is carried out in which vulcanizing agents are added

(Dam Gate Rubber Seal Prepared by Extrusion or Molding Methods)

EXTRUSION PROCESS

- Toi Control porosity of seals. (porosity reduces the strength & life of rubber seal.)

- Dimension accuracy (it helps to fit property & hence effects in performance at end)

- Fast production with accuracy (it helps in timely delivery & making the process help free for workers)

- Tensile strength property achievement (due to extrusion of rubber properly & hence increase the most important property of tensile strength.)

VULCANIZING (CURING)

A seal gets once in completely Electrically automatic hydraulic presses. Where temperature ,pressure (5000 psi pressure capacity), Good smooth finishing & time are can be controlled automatically. We are also having alternate method & facility of curing in autoclave by using Steam This curing can be carried as per the technical requirement of product. Production of different Rubber Articles such as Dam gate rubber seal, O-ring, U’ring, V’seal, Rubber Rollers, Control valve Diaphragm, Pneumatic cylinder Rubber seal kit etc..

- Finishing : Cutting and finishing / Trimming of the product

- Testing : The Chemical and Physical properties in, government or private sector Laboratory.

- Inspection : Inspection specifications Are strictly followed by government norms & requirment. Inspection and quality control department certifies the product.

- Packing : All seals of inspection sent to dispatch department. When seals are cleaned again, silicon washing & coating to cover against weather. Packing and necessary labeling for desired destinations.

- Shipping, Delivery : Dispatch : via best shipping companies, also on door delivery basis.(as per costumer requirement)

Features:

- Withstand atmospheric condition

- Efficient and long lasting use

- Low maintenance